Floway offer more Flow control technologies and services:

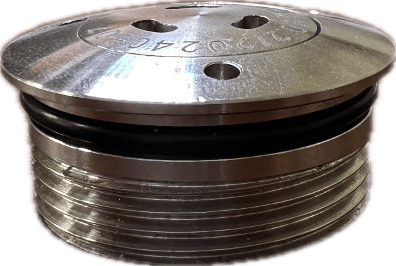

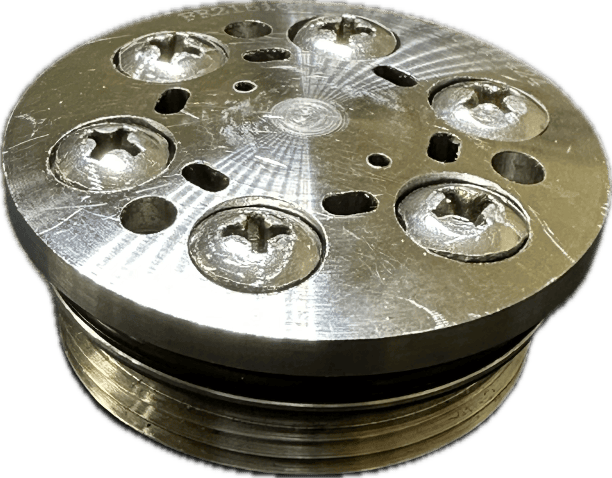

Autonomous Production Valve (APV)

The Autonomous Inflow Control Device (AICD) is highly effective at restricting the flow of unwanted fluids while allowing desired fluids to pass, making it a reliable tool in early and mid-phase well production. However, as the well matures and produces more unwanted fluids along its length, the AICD may restrict production across the entire lateral. In these later stages, operators often aim to maintain oil production, even in the presence of higher water cuts (WC), by increasing total liquid production.

In these scenarios, the Autonomous Production Valve (APV) complements the AICD by opening at higher production differentials, allowing the well to produce at higher liquid rates, which may be necessary to sustain oil production during high WC phases. The APV remains closed during the early stages of production and opens only when the differential pressure (DP) reaches a threshold, allowing for increased rates without sacrificing control over fluid flow. The APV is also reversible, meaning it can close once DP decreases, providing flexible, surface-controllable production.

By using AICDs in conjunction with APVs, operators can enhance well management across its lifecycle. AICDs remain an excellent choice for early-stage production, and the addition of APVs ensures high production rates can be maintained as conditions change. This combined approach mitigates the risks of deploying AICDs alone in uncertain conditions while offering an additional safeguard for long-term, high-rate production.

Autonomous Injection Valve

Floway's Xflow™ injection valve is designed to ensure more uniform flow distribution along horizontal wells, preventing excessive flow through high-permeability areas or fractures. This leads to more efficient utilization of injection flow, optimizing the overall injection process.

The valve operates by adjusting flow based on pressure changes. When flow reaches a certain threshold, it partially closes to maintain consistent flow sensing and regulation. The valve can reopen when pressure drops, allowing injection to resume efficiently, offering an "on/off" functionality for enhanced performance. Key features include:

- Even Injection Flow: The valve automatically reduces the flow rate when it exceeds a pre-set value, ensuring an even distribution of total flow among all valves.

- Even Injection Flow: The valve automatically reduces the flow rate when it exceeds a pre-set value, ensuring an even distribution of total flow among all valves.

- Fluid Property Insensitivity: The valve's performance remains consistent regardless of fluid properties like density or viscosity, ensuring reliable operation across different fluid compositions.

- Temperature and Chemical Environment Robustness: The valve maintains consistent performance irrespective of temperature, orientation, or chemical environment.

- Enhanced Durability: Constructed with tungsten carbide for superior erosion resistance, the valve ensures long-term reliability.This meticulously engineered design aims to provide unparalleled performance and reliability in injection applications, making it an ideal choice for demanding industrial environments.

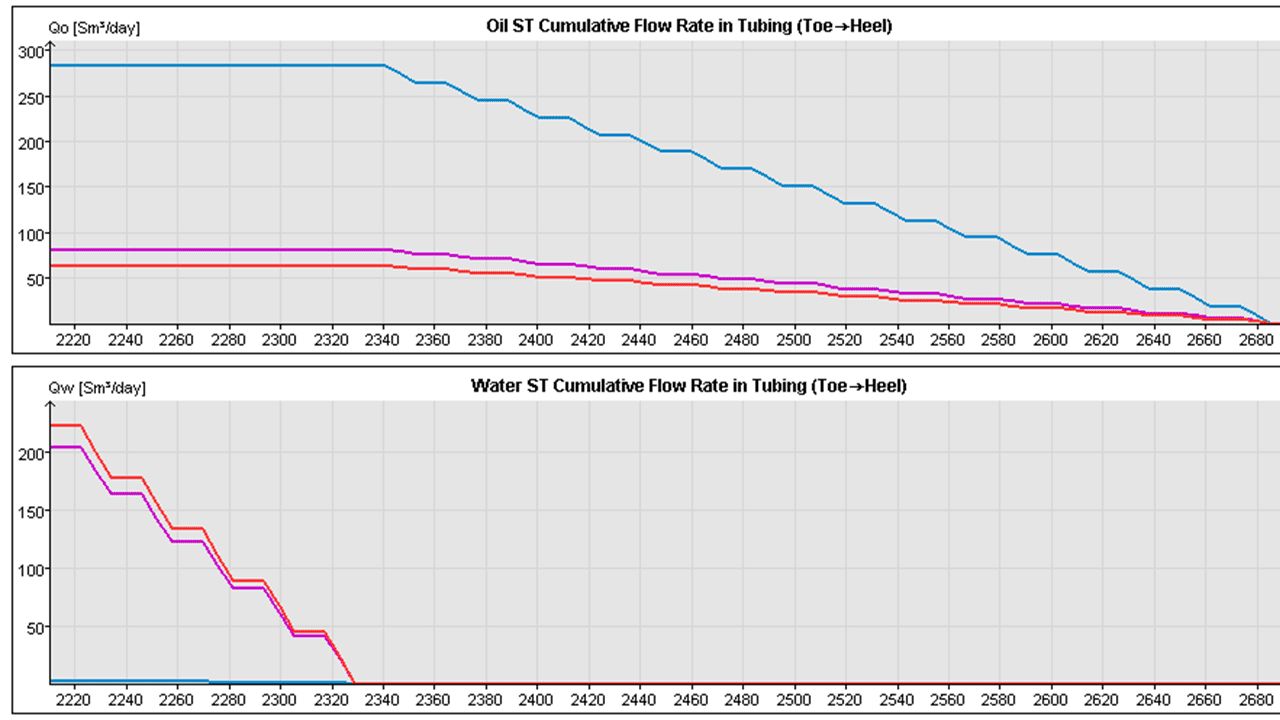

NETool simulation service for customer wells:

Combining the leading near wellbore simulator in the industry with a decade of inflow control device completion design experience, Floway is able to provide the best possible design to choke unwanted fluids effectively to increase ultimate hydrocarbon recovery.